CNC Machines

Bridging the Professional Gap

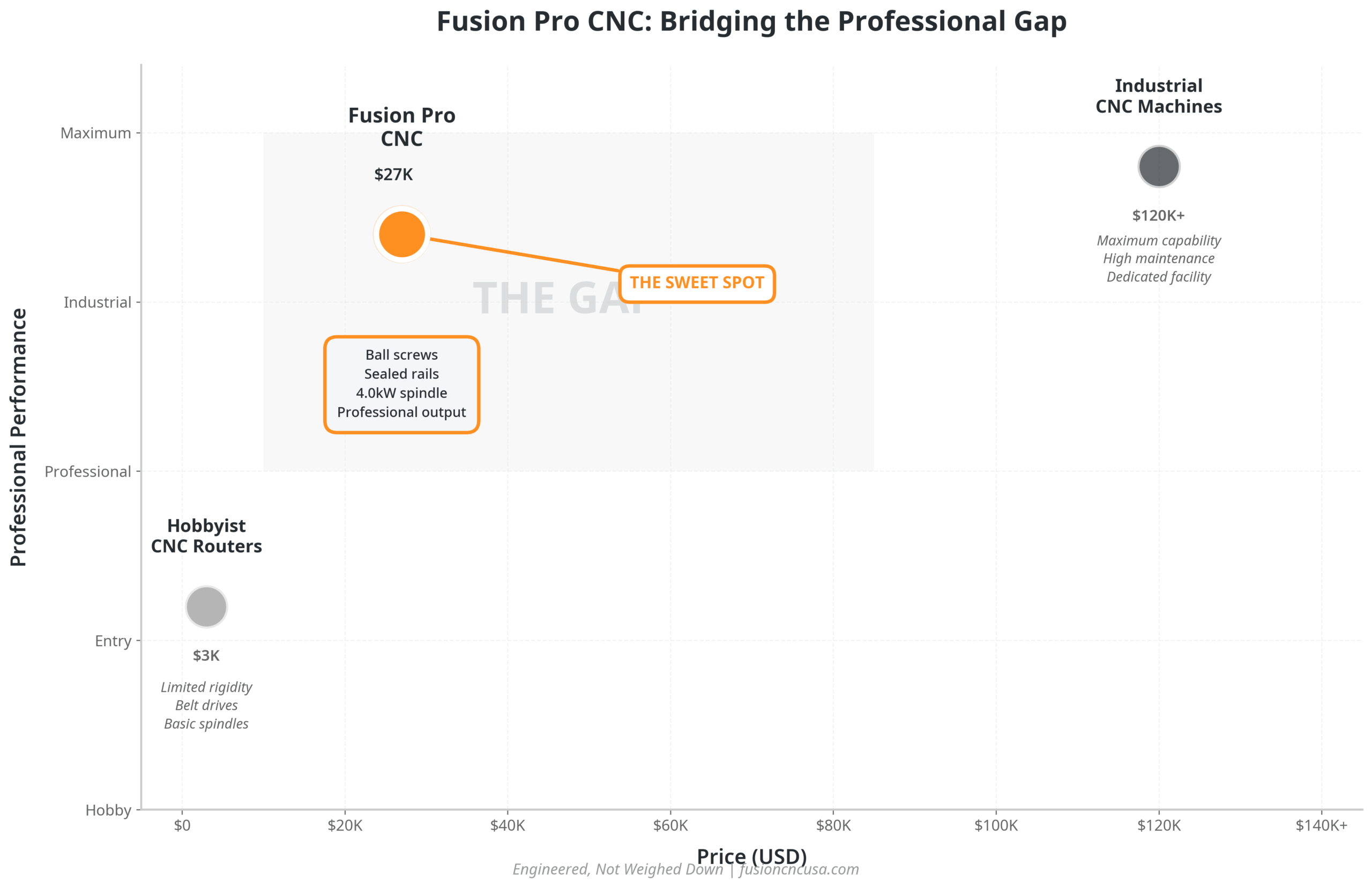

For years, the CNC market has been split into two worlds. Hobbyist routers that wobble under load, and industrial behemoths that cost six figures. Between them? A gap wide enough to frustrate every serious maker, small business owner, and technical educator in America. That gap is where Fusion CNC lives.

The Machine You Needed Finally Exists

We built the Fusion Pro CNC because we needed it ourselves. As engineers working on defense-grade projects, we understood precision. As makers running our own shop, we understood budget. And as problem-solvers by trade, we understood that the market was failing an entire class of professionals who deserved better.

What Makes a Professional CNC?

Professional doesn't mean expensive. It means engineered for performance, built for reliability, and backed by people who understand the work you do.

A professional CNC delivers consistent results under real-world conditions. It holds tolerances when cutting dense materials. It runs quietly enough for a classroom but powerfully enough for a production floor. It doesn't require a dedicated technician to keep it running, and it doesn't need to weigh 5,000 pounds to stay rigid.

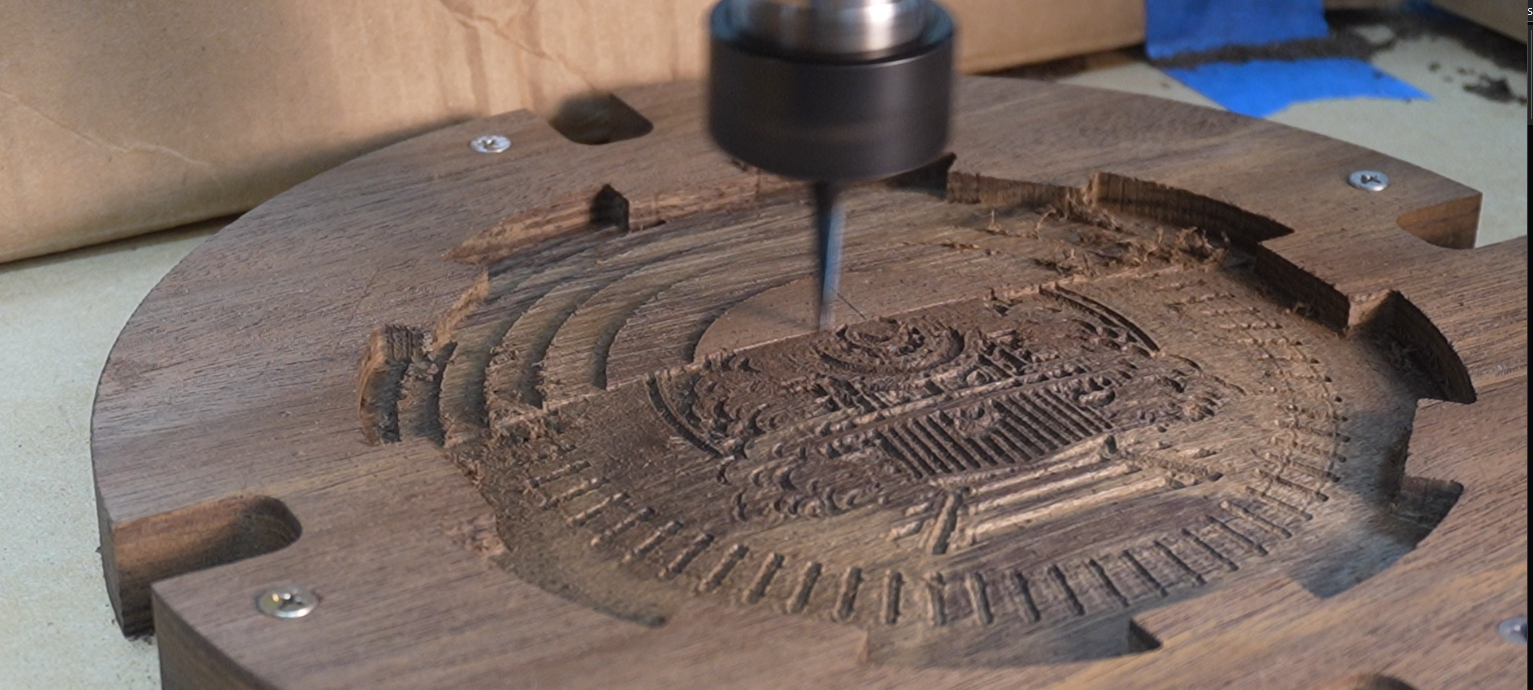

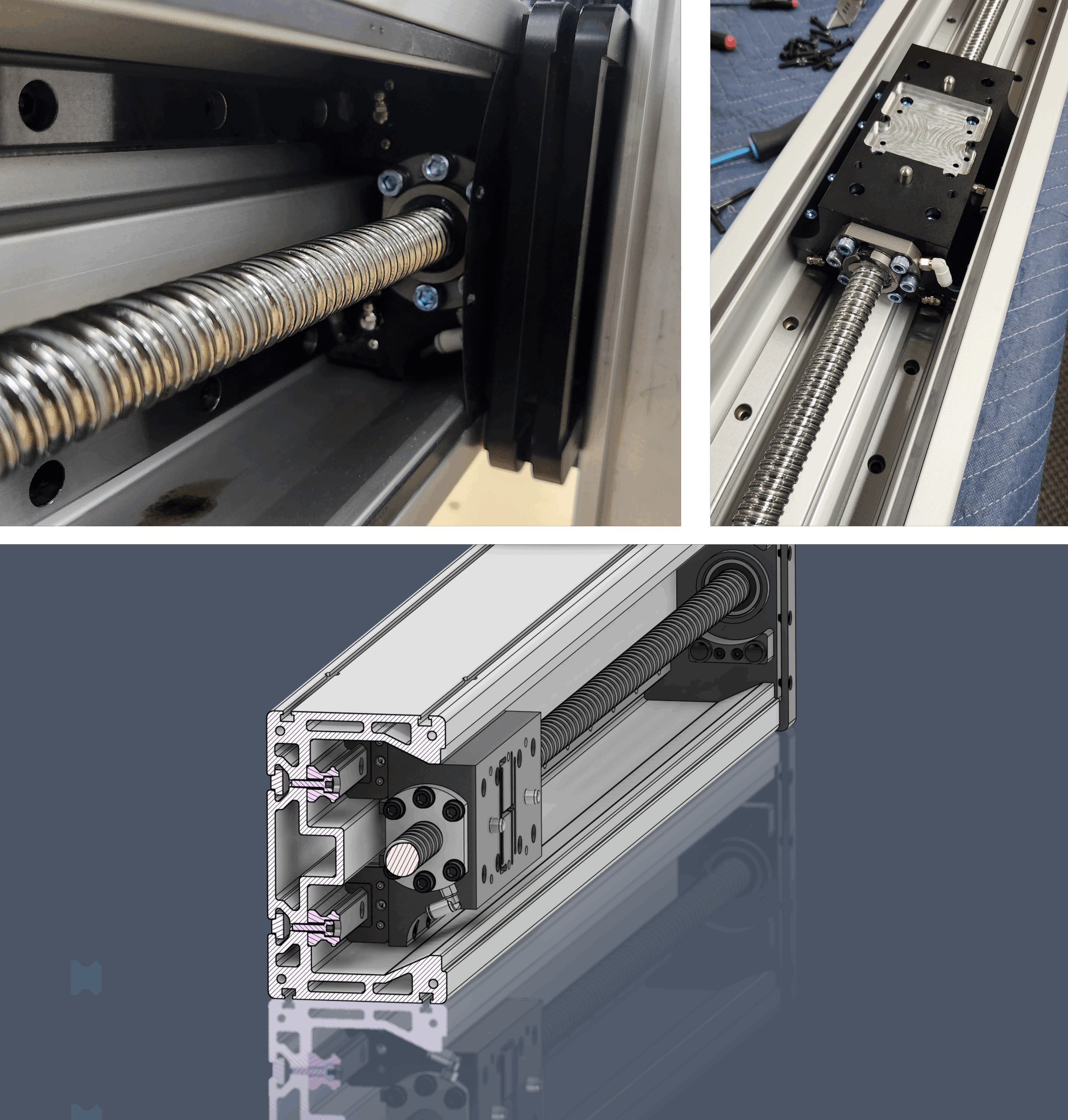

The Fusion Pro CNC achieves all of this through intelligent design. We use ball screws instead of belts for zero-backlash accuracy. We engineered sealed linear rails with spring-steel dust covers to keep debris out and performance consistent. We designed custom aluminum extrusions for each axis, built to handle real forces while staying true under load. And instead of relying on sheer mass for rigidity, we applied physics and finite element analysis to create a structure that's both strong and mobile.

The result is a machine that performs like industrial equipment but fits in a garage, school lab, or small production shop.

Why We Built Our Own

We didn't set out to become CNC manufacturers. We set out to solve a problem.

Our parent company, Kestrel Corporation, is an engineering R&D firm that supports defense and industrial clients. When we needed a CNC router for prototyping and fabrication, we tried the options available. Hobbyist machines couldn't handle the materials or tolerances we required. Industrial machines were overkill for our space and budget. So we did what engineers do: we designed our own.

We started with two machines, a hobbyist model and one we assembled from off-the-shelf components, and ran them side by side. We documented what worked, what failed, and where performance consistently fell short. From there, our mechanical engineer designed custom extrusions, selected precision components, and built a frame that could handle professional workloads without the industrial footprint.

Then we tested it. Not in theory, but in practice. We measured deflection under load, validated spindle torque with a Prony brake, tested positional accuracy with glass DRO scales, and pushed the machine through hundreds of hours of demanding cuts. Every claim we make is backed by data, not marketing.

When word got out, other makers, educators, and small manufacturers wanted one too. That's how Fusion CNC was born.

Filling the Gap: Where Fusion CNC Fits

The CNC market has long been divided into two extremes, leaving a massive void for professionals who need more than a hobby tool but don't require an industrial giant.

Hobbyist Machines

Affordable but Limited

Belt-driven systems, lightweight frames, limited power. Great for weekend projects, but they compromise on rigidity, precision, and professional output.

Fusion Pro CNC

The Professional Sweet Spot

Ball screw drives, sealed rails, 4.0 kW spindle, rigid frame. Industrial principles optimized for real workshops. This is where performance meets practicality.

Industrial Machines

Uncompromising Performance

Six-figure price tags, three-phase power, dedicated facilities. Exceptional capability, but out of reach for small businesses and independent makers.

This is the machine for furniture makers who outgrew their first router. For technical schools that need reliable, repeatable performance. For small manufacturers who can't justify a $100,000 investment but refuse to settle for hobbyist-grade output.

What You Can Expect from a Fusion Pro CNC

Precision You Can Measure

Deflection tests show just 0.008mm under maximum load, more than 15 times stronger than industry minimums. Positional accuracy validated with glass DRO scales down to the micron.

Power That Doesn't Quit

The 4.0 kW spindle delivers industrial-grade torque for clean cuts in hardwoods, composites, and dense materials. ClearPath servo motors provide closed-loop feedback for smooth, repeatable motion.

Reliability You Can Count On

Sealed rails with spring-steel dust covers keep chips out. Pre-lubricated maintenance ports make upkeep simple. A rigid frame design reduces vibration and wear.

Ease of Use Without Compromise

Ships with touchscreen Windows 11 controller, pre-configured software, and intuitive OpenBuilds interface. Compatible with VCarve, Aspire, Fusion 360, and most G-code outputs.

Built for Real Makers

The Fusion Pro CNC is designed for people who make things for a living, or want to. Furniture makers cutting dovetails and dados. Sign shops routing HDU and hardwoods. Technical schools teaching the next generation of fabricators. Small manufacturers prototyping parts and producing short runs.

These are the people who need precision they can trust, power they can rely on, and support they can reach. They don't need gimmicks or marketing hype. They need a machine that works, every time, without excuses.

That's what we built.

Learn More

Ready to see what professional-grade CNC performance looks like? Explore the Fusion Pro lineup, dive into our engineering and testing process, or schedule a live demo at our Albuquerque facility.